Glass Washing Machine ZYX2500A

This series glass washing machine is special designed for tempering line, laminating line, floating, coating and Low-e glass. It combined function of three step washing, used with frequency device driving system, which is easy to wash different size glass. Washing area installed with stainless steel or other special treatment steel. Optional for hard and soft brusher device, which is special designed for hard LOW-E glass washing. Machine can be design according to customer requirement. Notice: For this machine, except the frame of machine body is made by Iron, other air-knife\Machine guards(cover)\water tank all is used by stainless steel.

Keyword

glass washing machine

glass washing and drying machine

glass cleaning machine

Category

Field

Product Details

Mechanical introduction:

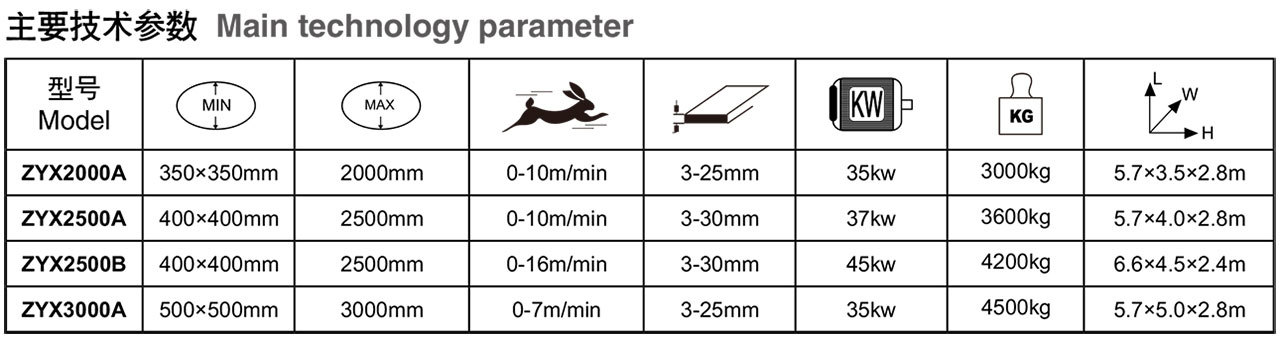

Glass washing machine ZYX2500A model is air knife type horizontal glass washing machine, the maximum washing width is 2500mm, and the maximum speed is 10m/min; standard equipped with frequency conversion speed regulation, two pairs of straight air knives, with electric integral lifting, soft brush washing Low-E glass and other functions. It is suitable for washing and blowing drying of flat glass, and is a necessary equipment for glass deep processing enterprises. Our glass washing machine series products are complete, including ordinary glass series, coated glass series, electronic photovoltaic glass series, etc. The thickness of the washing glass is from 3mm-50mm, the fastest speed customization can reach 18m/min, and the cleaning width is 1600-3300mm according to the requirements. The washing section and air drying can be lifted and lowered as a whole, with digital display. It can be specially designed according to user requirements. It is more conducive to connecting glass edging machine production line, glazing line, insulating glass production line, safety glass production line, etc.

Main features:

◆The glass cleaning machine main drive is gear transmission, frequency conversion speed regulation, digital display, and the brush roller rotation of the cleaning part is driven by the independent belt transmission of the upper and lower sets of motors, with stable rotation speed and long service life.

◆The sheet metal of the washing part in contact with the water is all made of stainless steel.

◆The whole washing machine conveying rubber roller adopts vulcanized rubber fully coated structure (it is strictly forbidden to contact acid liquid).

◆The washing department and air dry part are lifted as a whole, and the maximum lift is: 350mm, which is convenient for cleaning and maintenance.

◆Three pairs of brushes (φ150mm) configuration (washing LOW-E class selection: the upper brush is equipped with two hard brushes with cylinder lifting, plus a soft brush, washable LOW-E glass, ordinary coating and sunlight coated glass, two hard

Related Products