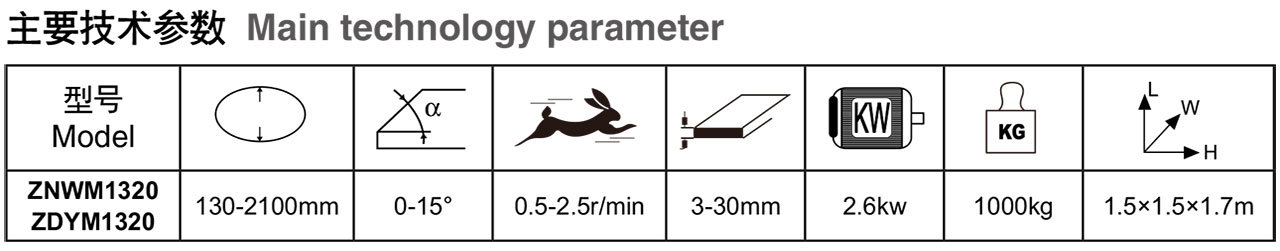

Glass Shape Grinding Machine ZDYM1320A

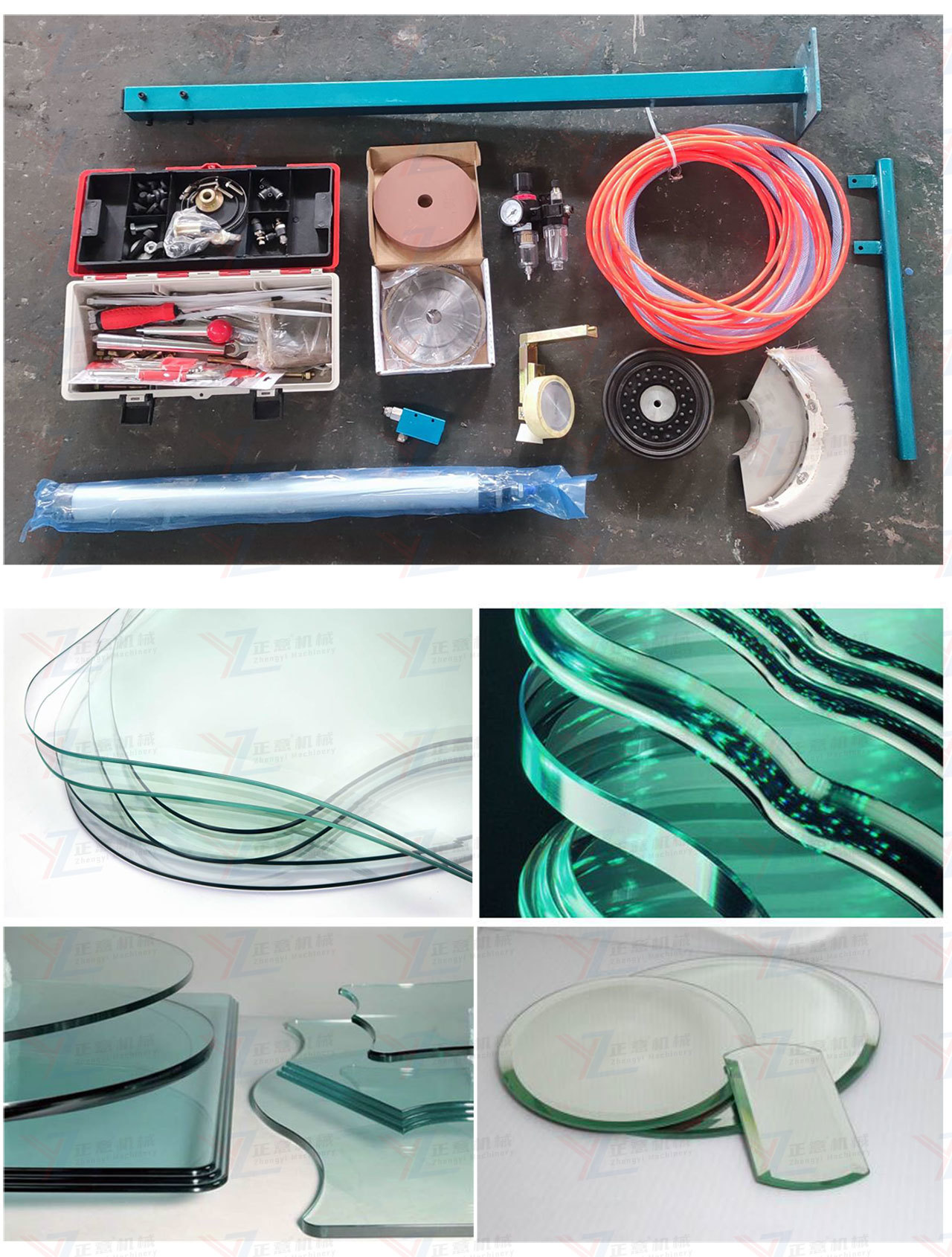

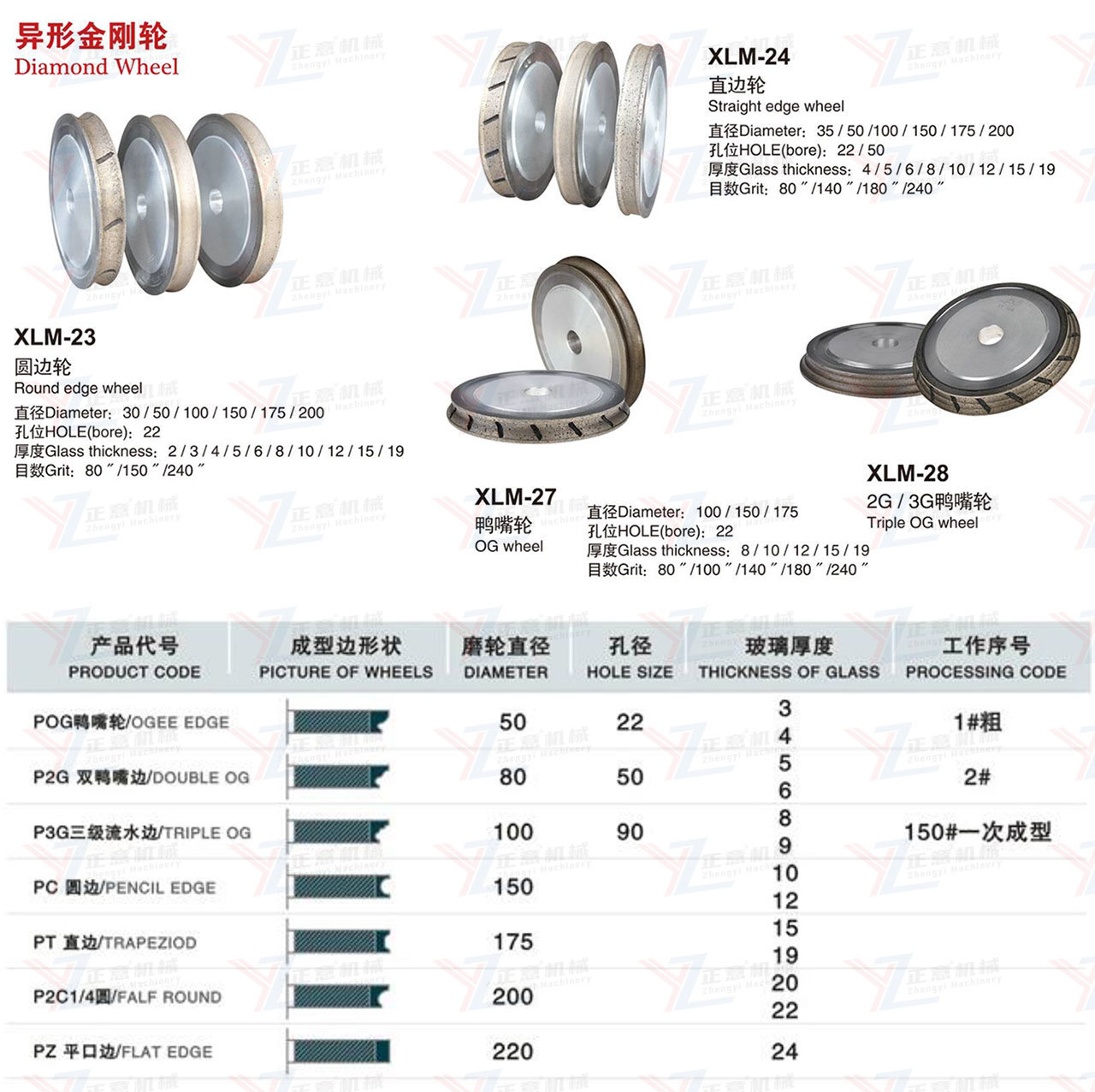

Glass shape beveling machine ZDYM1320A type is an upgrade of shape beveling machine ZDYM1320, the difference between the two models is that the grinding head lifting is upgraded from hand-cranked lifting to pneumatic lifting. The base, swing arm and five-star suction cup base of the special-shaped machine are castings, which are suitable for grinding and polishing round, oval and special-shaped glass round edges, OG edges, square edges and beveled edges. The glass is adsorbed on the suction cup by vacuum, and the continuously variable transmission drives the turntable to rotate or an independent satellite turntable on the separate drive disc rotates, so that the machine can process special-shaped flat glass with a rotation diameter of 700-2100mm and 100-700mm.The rotation speed of the turntable can be adjusted arbitrarily during operation. This machine can also semi-automatically grind simple shaped special-shaped glass by using a cylinder. When grinding the perimeter, three grinding wheels can be installed for rough, fine grinding and polishing. When grinding the beveled edge, install a bowl grinding wheel, tilt the grinding head back, and adjust the angle of the bevel to grind the end face. Main Features: ◆The base, large and small swing arms, and five-star suction cup seats that are rare in the industry are castings; ◆The continuously variable transmission drives the double worm gear to rotate to solve the problem of clearance in long-term use; ◆DELIXI, CHINT Electric; ◆Grinding head pneumatic lift. Note: Customers need to provide their own gas source, the air pressure can reach 0.6Mpa.

Keyword

Glass Shape Grinding Machine

glass shape bevelling edge machine

glass shape edging machine

Category

Field

Product Details

Mechanical introduction:

Glass shape beveling machine ZDYM1320A type is an upgrade of glass shape polishing machine ZDYM1320, the difference between the two models is that the grinding head lifting is upgraded from hand-cranked lifting to pneumatic lifting. The base, swing arm and five-star suction cup base of the special-shaped machine are castings, which are suitable for grinding and polishing round, oval and special-shaped glass round edges, OG edges, square edges and beveled edges. The glass is adsorbed on the suction cup by vacuum, and the continuously variable transmission drives the turntable to rotate or an independent satellite turntable on the separate drive disc rotates, so that the glass bevel polishing machine can process special-shaped flat glass with a rotation diameter of 700-2100mm and 100-700mm.The rotation speed of the turntable can be adjusted arbitrarily during operation. This machine can also semi-automatically grind simple shaped special-shaped glass by using a cylinder. When grinding the perimeter, three grinding wheels can be installed for rough, fine grinding and polishing. When grinding the beveled edge, install a bowl grinding wheel, tilt the grinding head back, and adjust the angle of the bevel to grind the end face.

Main Features:

◆The base, large and small swing arms, and five-star suction cup seats that are rare in the industry are castings;

◆The continuously variable transmission drives the double worm gear to rotate to solve the problem of clearance in long-term use;

◆DELIXI, CHINT Electric;

◆Grinding head pneumatic lift.

Note: Customers need to provide their own gas source, the air pressure can reach 0.6Mpa.

Related Products