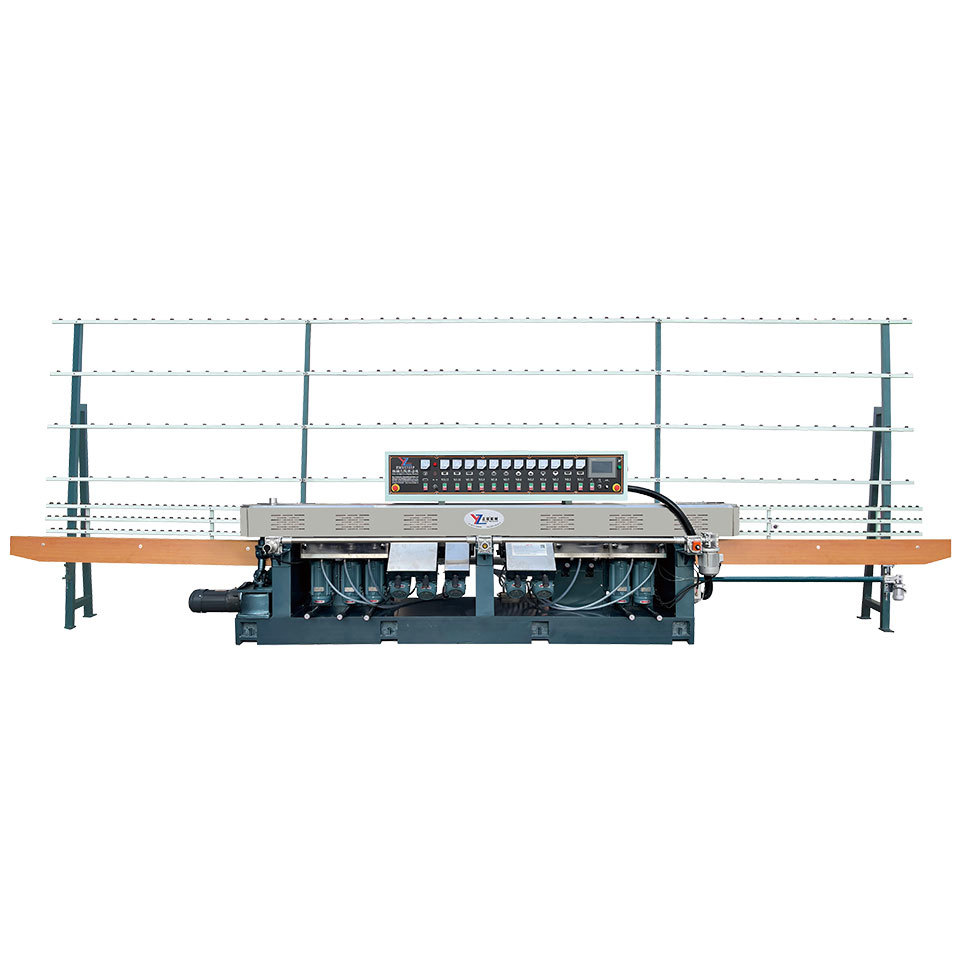

Horizontal glass edging machine ZWM10325

Mechanical IntroductionHorizontal glass straight edge grinding machine with 10 grinding motors, It is mainly used for grinding the bottom edge and large edges of flat glass. The distribution of the grinding heads is reasonable. There are 2 grinding flat edges, 2 grinding upper chamfers, 2 grinding lower chamfers, and the remaining 4 flat edges are finely ground and polished. The chamfering on this machine is fixed on the connected beam. When processing different thicknesses, there is no need to adjust the grinding amount of the chamfering. It is highly practical and easy to operate. It is the preferred edge grinding equipment for professional furniture, doors and Windows, kitchen and bathroom, craft, architectural engineering glass, rhombic, small pieces, long strips and large plate glass. ZWM10325 Main configuration table1Grinding motorManufactureJIANQIANG ,GuangdongModelGrinding 3.0KW、2.2KW、1.5KW2Main bearingManufactureNSK/ HRB3GovernorManufactureYUANXIN Frequency conversion4Worm gear boxManufactureZHUJIANGElectronic control component part5Electrical PartManufactureDELIXI6WireManufactureGuangdong Cable7Buttons, indicator lightsManufactureSchneider/Shanghai Ergong/Gaoqiao Main features:◆The grinding motor adopts a high-end dedicated motor of the brand, "DELIXI" brand electrical.◆2.2KW variable frequency speed regulator, ZHUJIANG worm gear box, more durable transmission;◆The grinding wheel is XINGLI brand, and the bottom polishing is SD001. After polishing, the effect is as bright as a mirror.◆The oil pump supplies oil to lubricate the grinding seat slide plate function, allowing for easy adjustment of the grinding head's advance and retreat.◆The upper and lower conveying synchronous belts at the inlet end are widened, and the lower end is simultaneously lengthened by 100 centimeters (ensuring stable glass conveying and preventing the appearance of large and small ends on the plates).◆There are belt guide rail pressure plates installed under the belts at the inlet and outlet ends◆The guide rail plate under the synchronous belt is made of high-molecular wear-resistant rubber material (ensuring the accuracy of operation and grinding volume).◆The support frame and the traveling power synchronous conveyor belt (synchronous conveying of large plates will not cause misalignment)◆The universal water pipe sprays each grinding head and grinding wheel, which can ensure sufficient water output to achieve cooling and reduce grinding wheel wear◆ When starting and stopping the control panel and adjusting the handle, there is an electricity meter display, which is safe and convenient◆ The upper compression beam is equipped with synchronous lifting at the front, middle and back (the glass compression is more stable, which can ensure that the straightness of the ground edge and the chamfer are consistent)◆With digital display (precise adjustment of glass thickness)

Keyword

Category

Field

glass grinding machine glass edging machine

Product Details

Mechanical Introduction

Horizontal glass straight edge grinding machine with 10 grinding motors, It is mainly used for grinding the bottom edge and large edges of flat glass. The distribution of the grinding heads is reasonable. There are 2 grinding flat edges, 2 grinding upper chamfers, 2 grinding lower chamfers, and the remaining 4 flat edges are finely ground and polished. The chamfering on this machine is fixed on the connected beam. When processing different thicknesses, there is no need to adjust the grinding amount of the chamfering. It is highly practical and easy to operate. It is the preferred edge grinding equipment for professional furniture, doors and Windows, kitchen and bathroom, craft, architectural engineering glass, rhombic, small pieces, long strips and large plate glass.

ZWM10325 Main configuration table | ||||

1 | Grinding motor | Manufacture | JIANQIANG ,Guangdong | |

Model | Grinding 3.0KW、2.2KW、1.5KW | |||

2 | Main bearing | Manufacture | NSK/ HRB | |

3 | Governor | Manufacture | YUANXIN Frequency conversion | |

4 | Worm gear box | Manufacture | ZHUJIANG | |

Electronic control component part | ||||

5 | Electrical Part | Manufacture | DELIXI | |

6 | Wire | Manufacture | Guangdong Cable | |

7 | Buttons, indicator lights | Manufacture | Schneider/Shanghai Ergong/Gaoqiao | |

Main features:

◆The grinding motor adopts a high-end dedicated motor of the brand, "DELIXI" brand electrical.

◆2.2KW variable frequency speed regulator, ZHUJIANG worm gear box, more durable transmission;

◆The grinding wheel is XINGLI brand, and the bottom polishing is SD001. After polishing, the effect is as bright as a mirror.

◆The oil pump supplies oil to lubricate the grinding seat slide plate function, allowing for easy adjustment of the grinding head's advance and retreat.

◆The upper and lower conveying synchronous belts at the inlet end are widened, and the lower end is simultaneously lengthened by 100 centimeters (ensuring stable glass conveying and preventing the appearance of large and small ends on the plates).

◆There are belt guide rail pressure plates installed under the belts at the inlet and outlet ends

◆The guide rail plate under the synchronous belt is made of high-molecular wear-resistant rubber material (ensuring the accuracy of operation and grinding volume).

◆The support frame and the traveling power synchronous conveyor belt (synchronous conveying of large plates will not cause misalignment)

◆The universal water pipe sprays each grinding head and grinding wheel, which can ensure sufficient water output to achieve cooling and reduce grinding wheel wear

◆ When starting and stopping the control panel and adjusting the handle, there is an electricity meter display, which is safe and convenient

◆ The upper compression beam is equipped with synchronous lifting at the front, middle and back (the glass compression is more stable, which can ensure that the straightness of the ground edge and the chamfer are consistent)

◆With digital display (precise adjustment of glass thickness)

Previous

Previous

Related Products