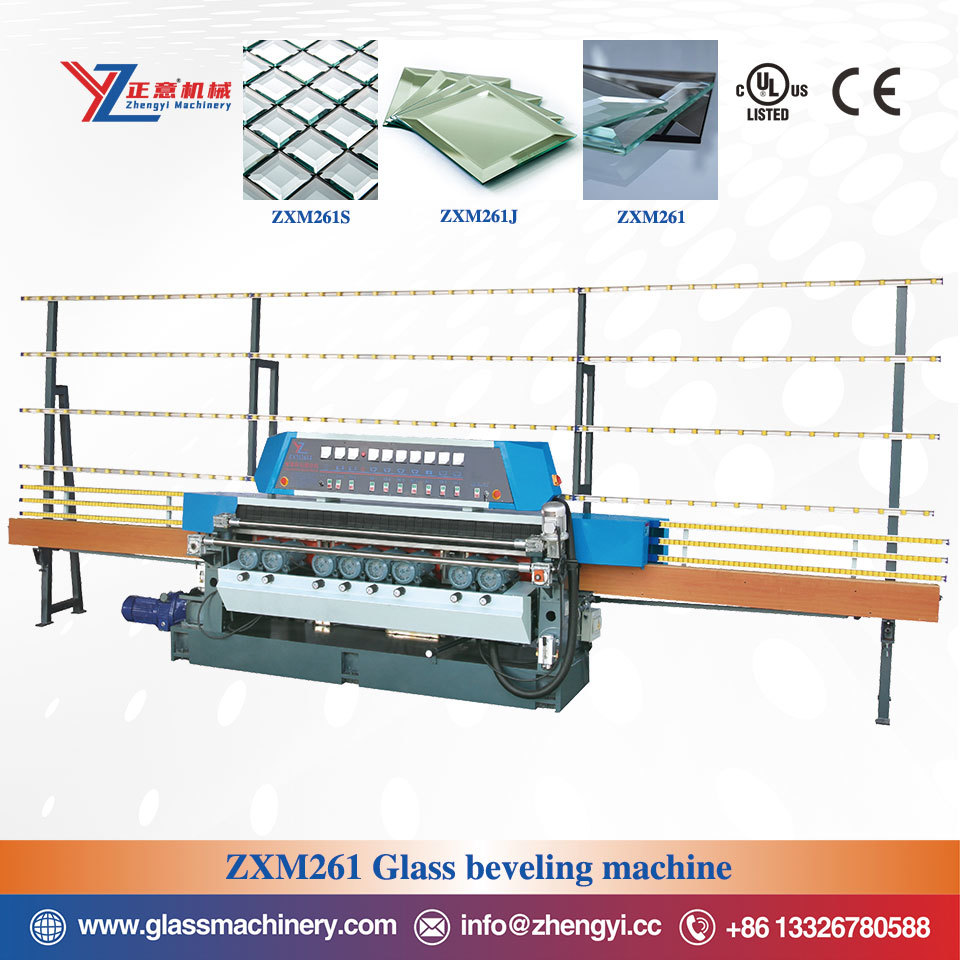

Glass Beveling Machine ZXM261P Series

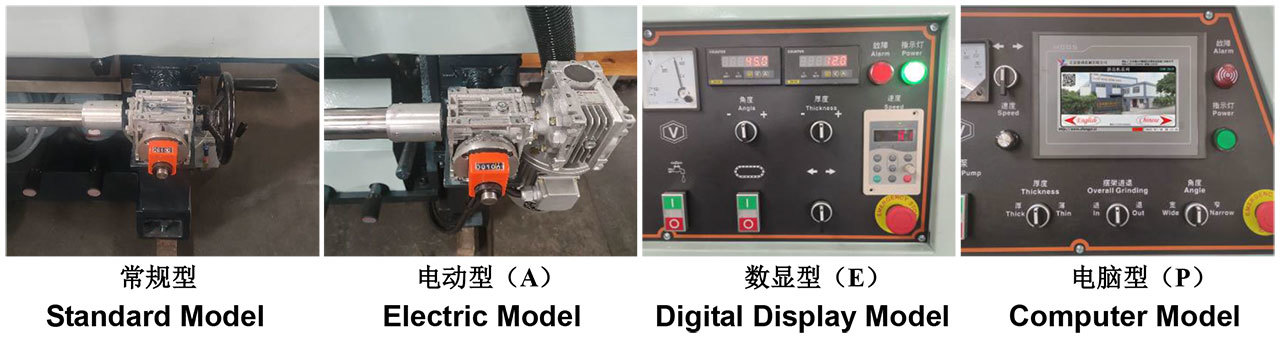

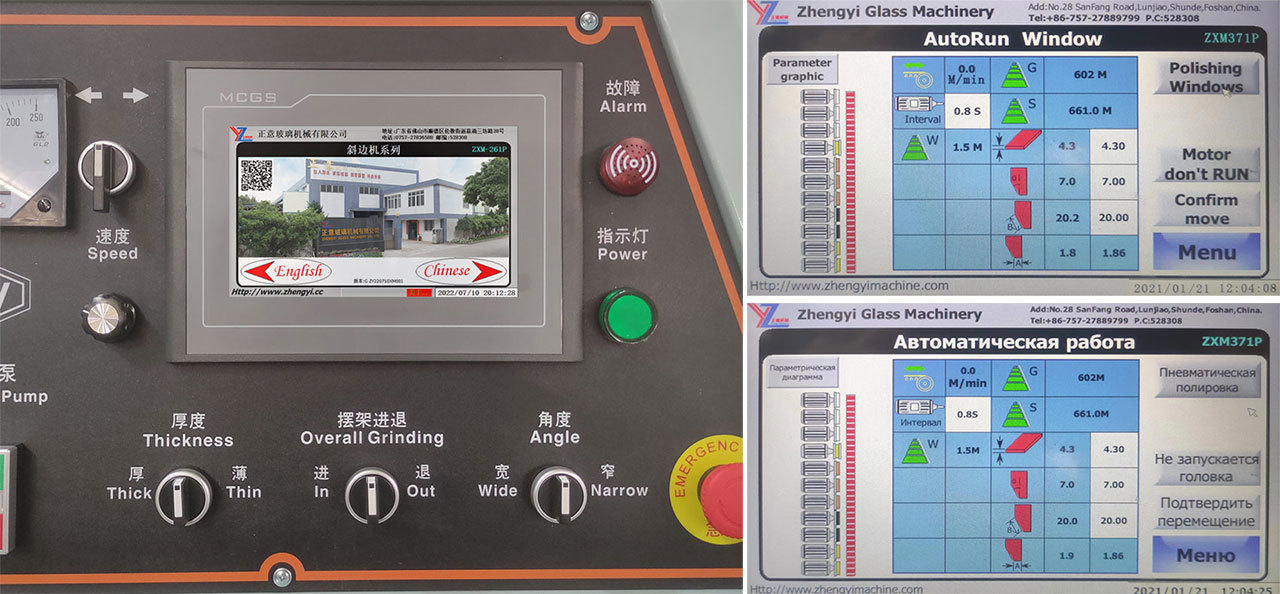

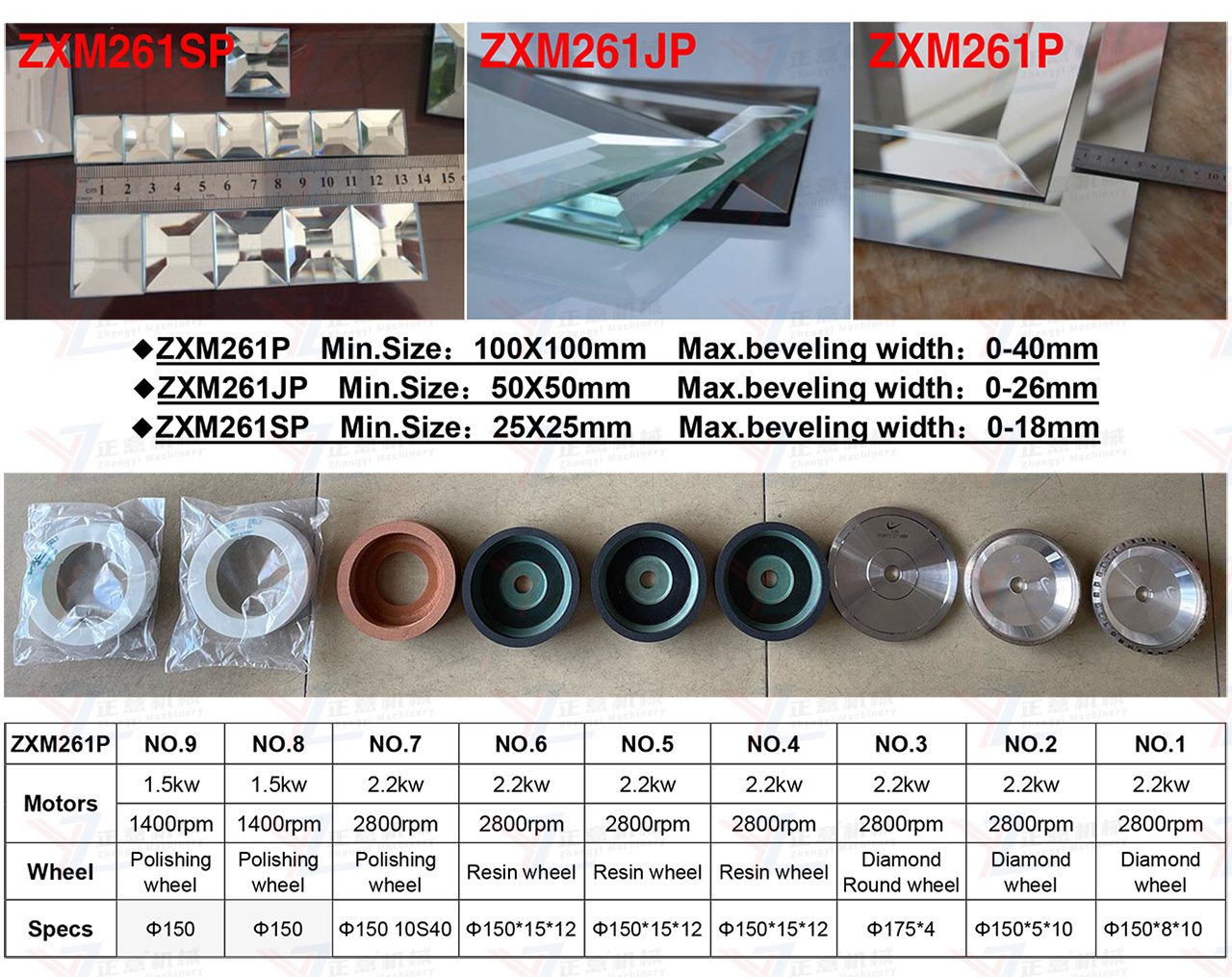

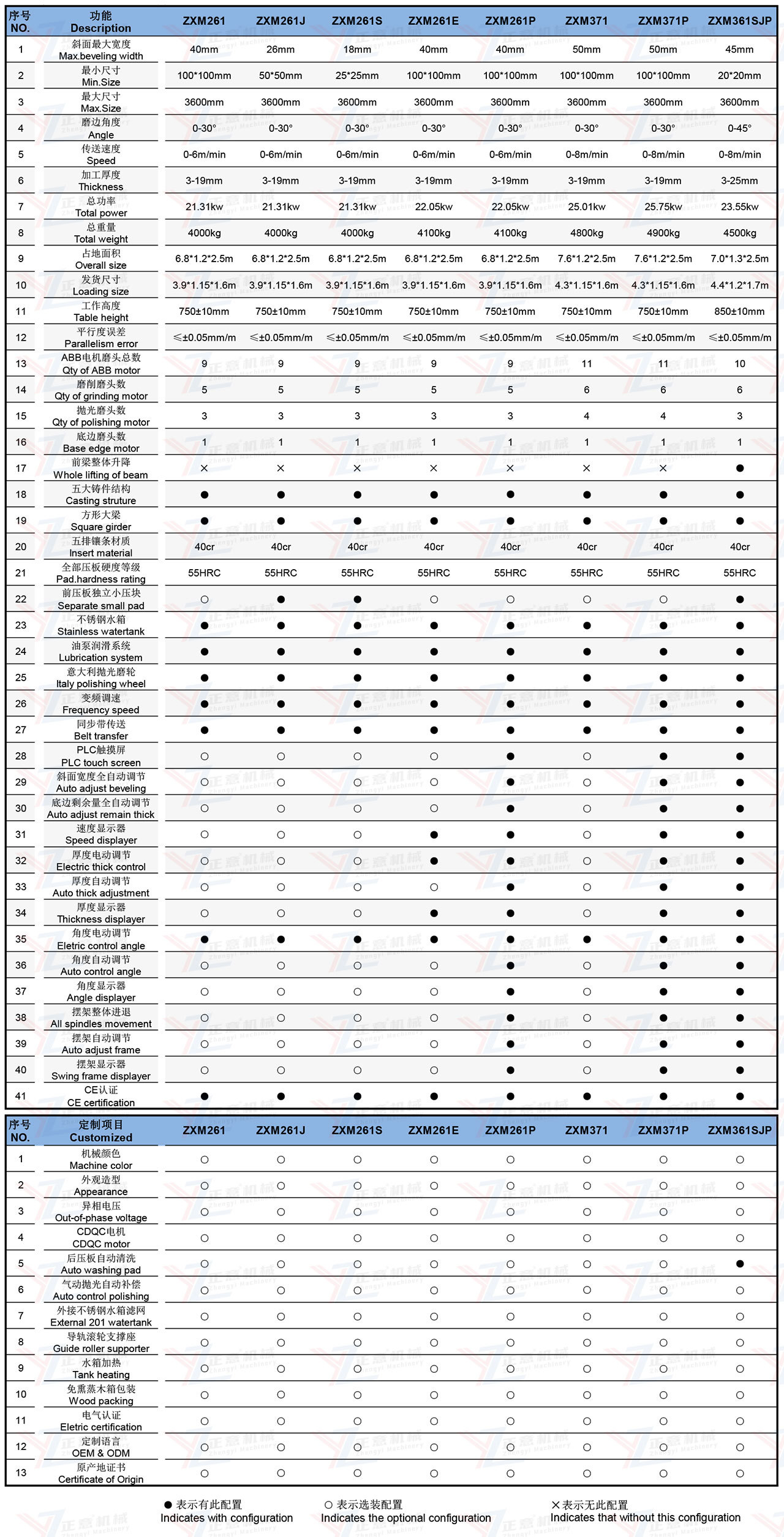

Glass bevel machine ZXM261P series for nine grinding head bevel machine, conventional models have three ZXM261P/ZXM261JP/ZXM261SP, the machine adopts PLC control system touch screen operation, bevel width one-key adjustment; The machine is suitable for grinding the straight beveled edge and bottom edge of flat glass, and the rough grinding, fine grinding, polishing and grinding of the bottom edge of the beveled edge are completed at one time, and the effect after polishing is consistent with the mirror surface. Direct grinding head motor, compact structure, low voice, few failures; The motor controls the overall swing angle of the twin screw, and has the function of integral advance and retreat of the grinding head swing frame; It has the advantages of advanced structure, high precision, convenient operation and strong stability, and is suitable for large-scale glass bevel edging processing. Main Features: ◆INOVANCE PLC, INOVANCE inverter, MCGS touch screen operation, with independent intellectual property rights operation interface; ◆Mechanical, operating system with trinity function, touch screen input bevel width, mechanical automatic adjustment; ◆Base, girder, swing frame, column, grinding head are high density casting parts, strong and stable fuselage; ◆ABB international brand grinding head motor; 2.2KW variable frequency motor wide range governor, ZHUJIANG worm gear box; ◆High quality alloy steel inserts of 40cr steel, the front and back pads are hardened and wear-resistant by 55 degrees high frequency quenching; ◆Front pads is combined with small pads construction structure, batch processing Mosaic glass loss splint without replacing the whole plate, reduce the cost of use; ◆Stainless steel water tank, two oil pumps on both sides respectively supply pressure plate, drag plate, lifting structure and other moving parts of lubrication; ◆Aluminum alloy scaffolding row; Italian BARBIERI synchronous belt transmission; Delxi brand electric; ◆High quality paint shield; unique waterproof technology, girder bottom with water brush; ◆Coarse grinding wheel, fine grinding wheel, polishing wheel all use “XINGLI” brand, fine polishing wheel and felt wheel we use Italian wheels.

Keyword

Glass bevel machine

glass bevel polishing machine

glass straight line beveling machine

Category

Field

Product Details

Mechanical introduction:

Glass beveling machine ZXM261P series for nine grinding head bevel polishing machine, conventional models have three ZXM261P(min glass:100*100mm,max beveling width:40mm)/ZXM261JP(min glass:50*50mm,max beveling width:25mm)//ZXM261SP(glass mosaic machine,min glass:25*25mm,max beveling width:18mm), the machine adopts PLC control system touch screen operation, bevel width one-key adjustment; The machine is suitable for grinding the straight beveled edge and bottom edge of flat glass, and the rough grinding, fine grinding, polishing and grinding of the bottom edge of the beveled edge are completed at one time, and the effect after polishing is consistent with the mirror surface. Direct grinding head motor, compact structure, low voice, few failures; The motor controls the overall swing angle of the twin screw, and has the function of integral advance and retreat of the grinding head swing frame; It has the advantages of advanced structure, high precision, convenient operation and strong stability, and is suitable for large-scale glass bevel edging processing.

Main Features:

◆INOVANCE PLC, INOVANCE inverter, MCGS touch screen operation, with independent intellectual property rights operation interface;

◆Mechanical, operating system with trinity function, touch screen input bevel width, mechanical automatic adjustment;

◆Base, girder, swing frame, column, grinding head are high density casting parts, strong and stable fuselage;

◆ABB international brand grinding head motor; 2.2KW variable frequency motor wide range governor, ZHUJIANG worm gear box;

◆High quality alloy steel inserts of 40cr steel, the front and back pads are hardened and wear-resistant by 55 degrees high frequency quenching;

◆Front pads is combined with small pads construction structure, batch processing Mosaic glass loss splint without replacing the whole plate, reduce the cost of use;

◆Stainless steel water tank, two oil pumps on both sides respectively supply pressure plate, drag plate, lifting structure and other moving parts of lubrication;

◆Aluminum alloy scaffolding row; Italian BARBIERI synchronous belt transmission; Delxi brand electric;

◆High quality paint shield; unique waterproof technology, girder bottom with water brush;

◆Coarse grinding wheel, fine grinding wheel, polishing wheel all use “XINGLI” brand, fine polishing wheel and felt wheel we use Italian wheels.

Related Products